Simple Molding Scraper Plane

© Frank Ford, 7/13/99; Photos by FF, 7/13/99

I'm making the new ten string ebony bridge for a circa 1850 Martin harp guitar, which has a little cove cut at the back edge. Now, I could set up a router with a round nose bit of the right diameter, that is, if I actually had the bit, which I don't.

So I think to myself, "What would Mario do?"

Here's what I came up with.

It's a little one-use molding plane with a 90 degree cutting angle. It took about 15 minutes to make this little tool from scratch, and about the same length of time to make the 6-inch cut I needed. Speed isn't everything, but I mention it because I was pleased at how fast and easy things went.

First, I took a scrap of hardwood and cut a rabbet on one face with my back saw by hand, truing it up with my little Clifton rabbet plane:

My cutter is just an old file, and I quickly ground the little round nose shape on my grinder, and sharpened it crudely, honing it with a little diamond pocket file:

I cut a notch slightly wider than the file in the broad face of my rabbet:

Clamping the block in my vise, I simply inserted the cutter and tapped in an oversize wedge to hold it:

Here's what the tool looked like, set up:

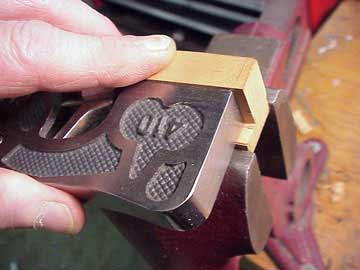

And here's a close-up of the cutting blade with the tool in the vise, ready for use:

Only the bottom rounded part of the blade is the sharp part which will actually do the cutting.

I scraped my roughed-out bridge across the cutter blade, and tapped the blade to deepen the cut after each pass.

See? It's all done, and just about as neatly as a router cut:

As a final step, I'll true up the cut with a dowel wrapped over with fine sandpaper.

Over and over I remind myself to think of the "old time" hand process. Sometimes, it's not only simpler, but actually faster and easier. . .