Regluing loose bridges is standard fare for most guitar repair shops, and it's usually successful, resulting in a healthy guitar.

Steel string guitar

Examining Cracked Bridges

© Frank Ford 2006; Photos by FF

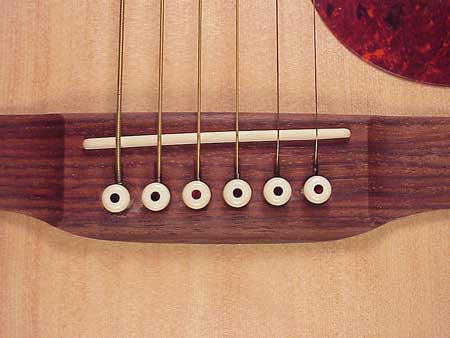

For most of the last hundred years, we've counted on flat top guitar bridges to resist the load of up to around 180 pounds of relentless string tension, to transfer the strings' vibrating energy to the top and to support a saddle that determines action height and intonation. The choice material for bridges has traditionally been ebony or rosewood because these two woods are among the most dense, stiff and strong in the world. But, sometimes they fail - either pulling loose from the top to which they are glued or actually breaking under the load of string tension.

A car parked in the sun can develop interior temperature in excess of 150

degrees Fahrenheit. At that temperature, the glue that holds the bridge may

start to fail, and the bridge will become noticeably loose from the top:

Regluing loose bridges is standard fare for most guitar repair shops, and it's

usually successful, resulting in a healthy guitar.

Structural failures of the bridge itself are often best addressed by replacement of the entire bridge. Unlike other structural parts of the guitar, the bridge must withstand a constant load, which, in the case of damage or poor design, may be concentrated in specific areas of the bridge, amounting to more than either the wood or any glue can handle. While a bridge may develop stress cracks in any position as a result of dryness caused heat and/or low humidity, the two most commonly seen structural failures of steel string bridges are cracks through the line of bridge pin holes, and cracks in the area that supports the saddle. Wood is most likely to crack along the grain lines, and guitar bridges are always constructed with the grain oriented lengthwise, perpendicular to the pull of the strings.

Here's a classic break. The forward tension on the saddle was simply more than

the bridge could handle. Either a small weakness in the grain, or a poorly fit

saddle may have been responsible:

As if the bridge weren’t vulnerable enough, it has a deep groove cut in

it that must support a saddle against which the strings bear mightily. If the

saddle is too high or the slot too shallow there might not be sufficient strength

to handle the forward thrust of the saddle as it is pulled by six steel strings

tuned to pitch. It’s a matter of leverage by which the saddle can simply

split the bridge along its grain lines. Here's a too-high saddle, and it is

really testing the strength of the ebony bridge:

Sometimes, the addition of an under-the-saddle pickup element is the last straw. Raising the saddle by the customary 1/16” may be just enough in some bridge and saddle combinations to increase the leverage against the front edge of the saddle slot, and the bridge may break catastrophically:

If the saddle fits very loosely, it will bear right on that upper edge of the slot, and the forward pull of the strings may be magnified enough to cause a similar crack. A bridge cracked at the saddle is hardly ever repairable. Most of the time the only logical course of action is to replace the bridge, preferably with one that has a better geometry – a taller bridge with a lower saddle or a deeper slot to accommodate the pickup element.

Some makers try to minimize the tendency to crack through the line of holes by orienting the holes in an angled or circular pattern so they don’t line right up with the wood grain:

The bridge above has an added bonus - since the pin holes are lined up parallel to the saddle there's a more even down pressure (break angle) on the saddle for each string.

Synthetic materials such as high pressure laminated phenolic (Micarta) or epoxy/carbon fiber composites might indeed make for a superior and indestructible bridge, but the acoustic guitar remains a traditional stringed instrument, so these materials have not accrued much favor to date.

A common misconception is that bridges crack between the bridge pin holes

because someone has rammed the tapered bridge pins in too far, or that wooden

bridge pins have swollen enough to exert the force necessary to cause a crack.

In fact, there are a number of more likely explanations. Bridges that are very

thin may be too weak to resist the string tension and may bend under the load.

While the wood of the bridge is very strong, it is also quite brittle and can

crack easily if subjected to this kind of bending. So, if your guitar bridge

is thinner than about 1/4” in the region of the bridge pin holes, it may

be thin enough to crack because it is simply too weak:

Another major cause for this particular crack is a failure of another important element. Under the top, roughly aligned with the bridge, there is a hardwood reinforcement called the “bridge plate.” Here's a cross section of a healthy guitar top, with a nice bridge and saddle configuration, a pickup under the saddle and a nice flat maple bridge plate under all of it:

The bridge plate has two basic jobs – to reinforce the tender spruce against

the wear and upward pull of the string balls, which are held against it by the

bridge pins, and to help keep the top stiff and flat under the bridge.

This bridge plate is mahogany, a wood that's clearly too soft for the job:

Notice how the string balls have pulled right up into the plate. Now, they're

starting to bear directly on the bottom of the bridge, increasing the possibility

that the bridge will bend and crack between the holes.

An older instrument may have undergone hundreds of string changes, and the bridge plate may have become worn or chipped along the line of the bridge pin holes:

Often enough this wear is enough to weaken the bridge plate significantly in

this region, contributing to a bending force on the bridge, ultimately causing

that familiar crack:

Or, the wear may result in enlarged bridge pin holes such that the string balls pull up directly against the bottom surface of the bridge itself, increasing the likelihood of bridge and/or top failure

In the excess heat of a car parked in the sun, the glue bonds between the

top, bridge and bridge plate may weaken enough to allow the entire assembly

to bend under the load of string tension. While this kind of heat usually results

in a loose bridge, it is also a major cause of bridge cracks. Even if the result

is only a loose bridge, it may be accompanied by a crack in the bridge plate

that might go unnoticed when the bridge is reglued.

Later, the cracked bridge plate may contribute to the cracking of the bridge

as the top flexes in that area, pulled by the string balls

A bridge cracked through the line of bridge pin holes may possibly be glued

but it is important to recognize the original cause of the crack. So, most of

the time, it’s a good idea to reinforce the bridge plate with a substantial

layer of hardwood, about 3/32” thick. If the grain is oriented parallel

to the direction of the string pull (perpendicular to the crack in the bridge)

even such a thin layer will add tremendous strength to the whole assembly, while

having little if any effect on tone:

Complete bridge plate replacement is another good alternative to correct the

worn or damaged plate that can cause cracks, but it is a process with more complexity

and possible risks.

Replacing the bridge is a more certain way to assure continuing support for the string tension, but even then it may be desirable to overlay or replace the bridge plate for extra insurance. The new bridge may well be free from a defect in the grain that may have contributed to the crack, too.

A parting shot from the rogues gallery:

Screws are not a good way to try to fix anything on a guitar bridge!

Back to Index Page